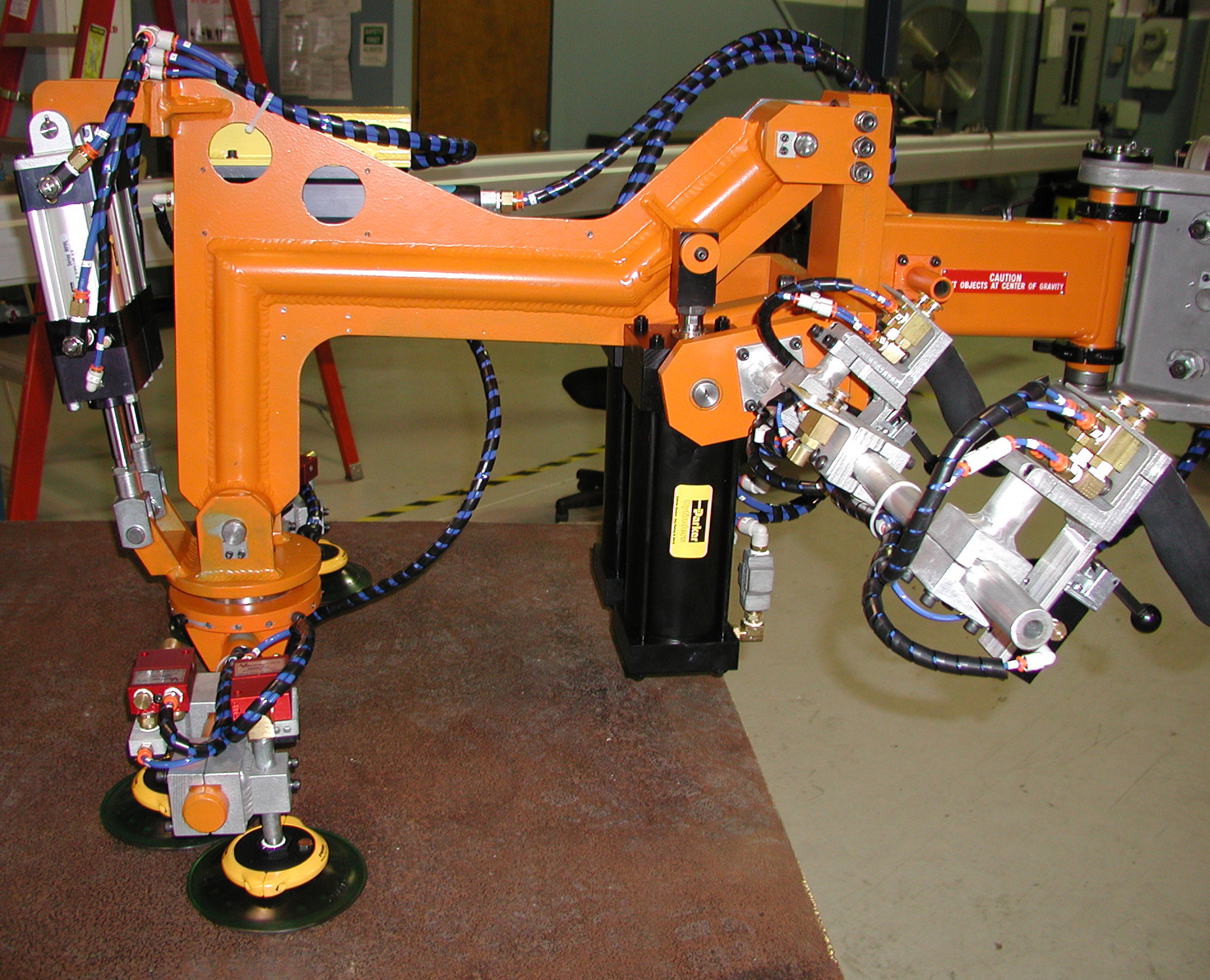

Jomat Industries can help you stay ahead of the competition with innovative solutions designed to meet your company's need for productivity, ergonomics, reliability & quality.

Our expert staff of designers, engineers & support personnel are dedicated to the goal of providing you with high quality ergonomic products: